INCT GmbH

Solutions Details

INCT Smart Assembly Line Solution for New Energy Battery Module & PACK Production

Industry Background

With the rapid growth of the new energy vehicle and energy storage industries, the manufacturing of battery modules, PACKs, and CTP systems demands ever-higher levels of precision, stability, and automation.

These production lines typically operate 24 hours a day, requiring equipment with high reliability, long service life, and flexible configuration to support diverse assembly processes.

To meet these challenges, INCT has developed a comprehensive automation solution for the new energy battery industry. The system integrates INCT’s servo presses, linear modules, ball screw & guide assemblies, gearboxes, and electric cylinders—delivering an intelligent, mechatronic platform for efficient and consistent battery assembly.

Solution Components

The solution is built upon INCT’s core products, forming a complete motion and control system:

1️⃣ INCT Servo Press

Designed for module forming and PACK press-fit processes. Offers high-precision force control and real-time pressure curve monitoring to ensure consistent quality.

2️⃣ INCT Linear Module

Rigid, high-speed linear motion platform supporting multi-axis coordination for assembly and handling stations.

3️⃣ INCT Ball Screw & Guide Assembly

Provides precise and durable linear motion, maintaining repeatability and stability under long-term operation.

4️⃣ INCT Gearbox

Delivers high torque with low backlash for efficient and smooth servo motion transmission.

5️⃣ INCT Electric Cylinder

A clean, precise, and low-maintenance alternative to pneumatic and hydraulic systems—ideal for press-fit, pushing, and holding applications.

Key Features

👉 24/7 Reliable Operation

All systems are designed with precision motion components and servo control for continuous production stability.

👉 High Accuracy and Consistency

Closed-loop control of pressure, position, and torque ensures process traceability and product uniformity.

👉 Mechatronic and Modular Design

Highly integrated components allow flexible configurations for different production layouts and cycle times.

👉 Comprehensive Product Portfolio

INCT provides a wide range of motion and automation products to support various battery structures, including prismatic, cylindrical, solid-state, and energy storage cells.

Typical Applications

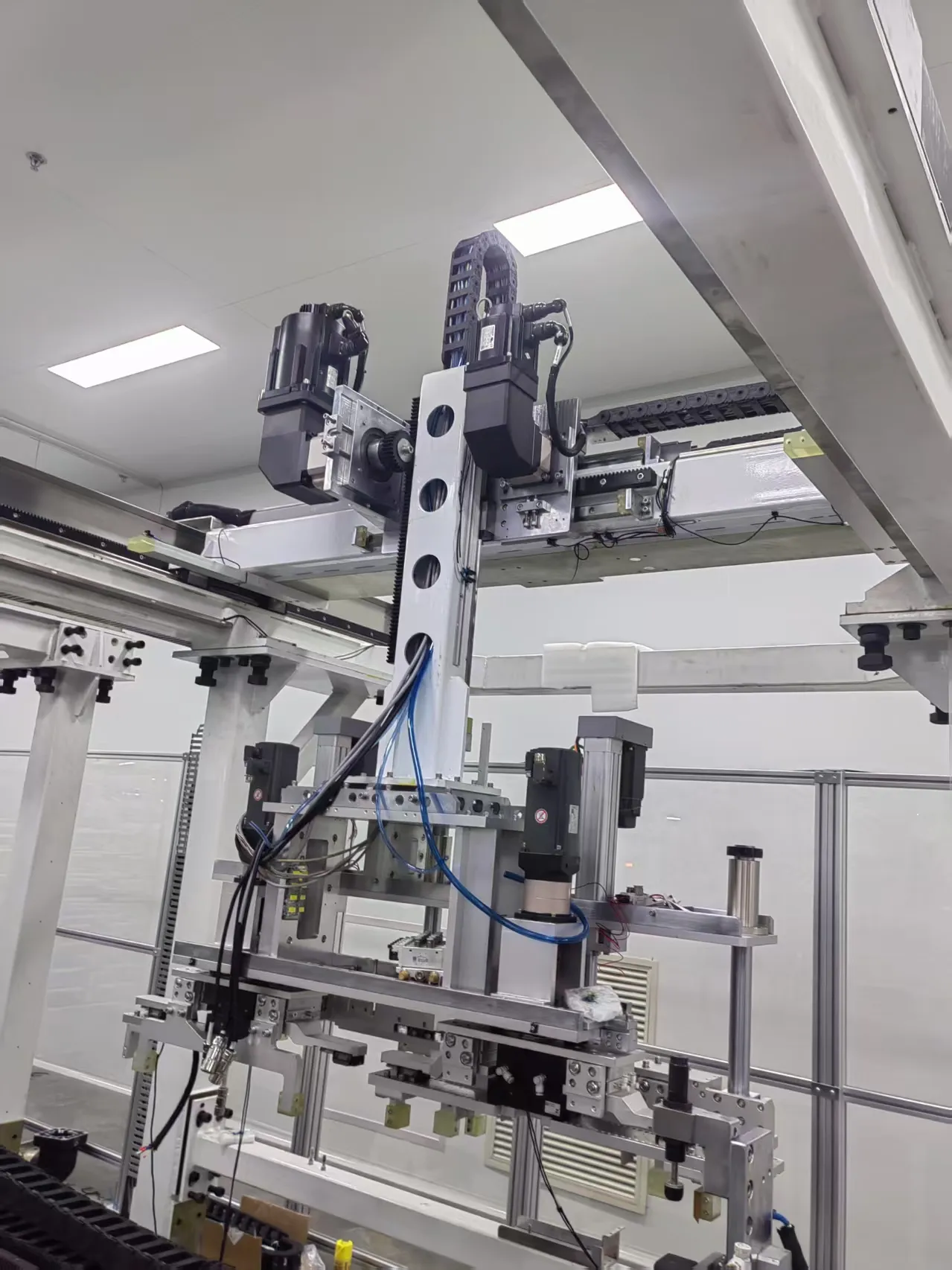

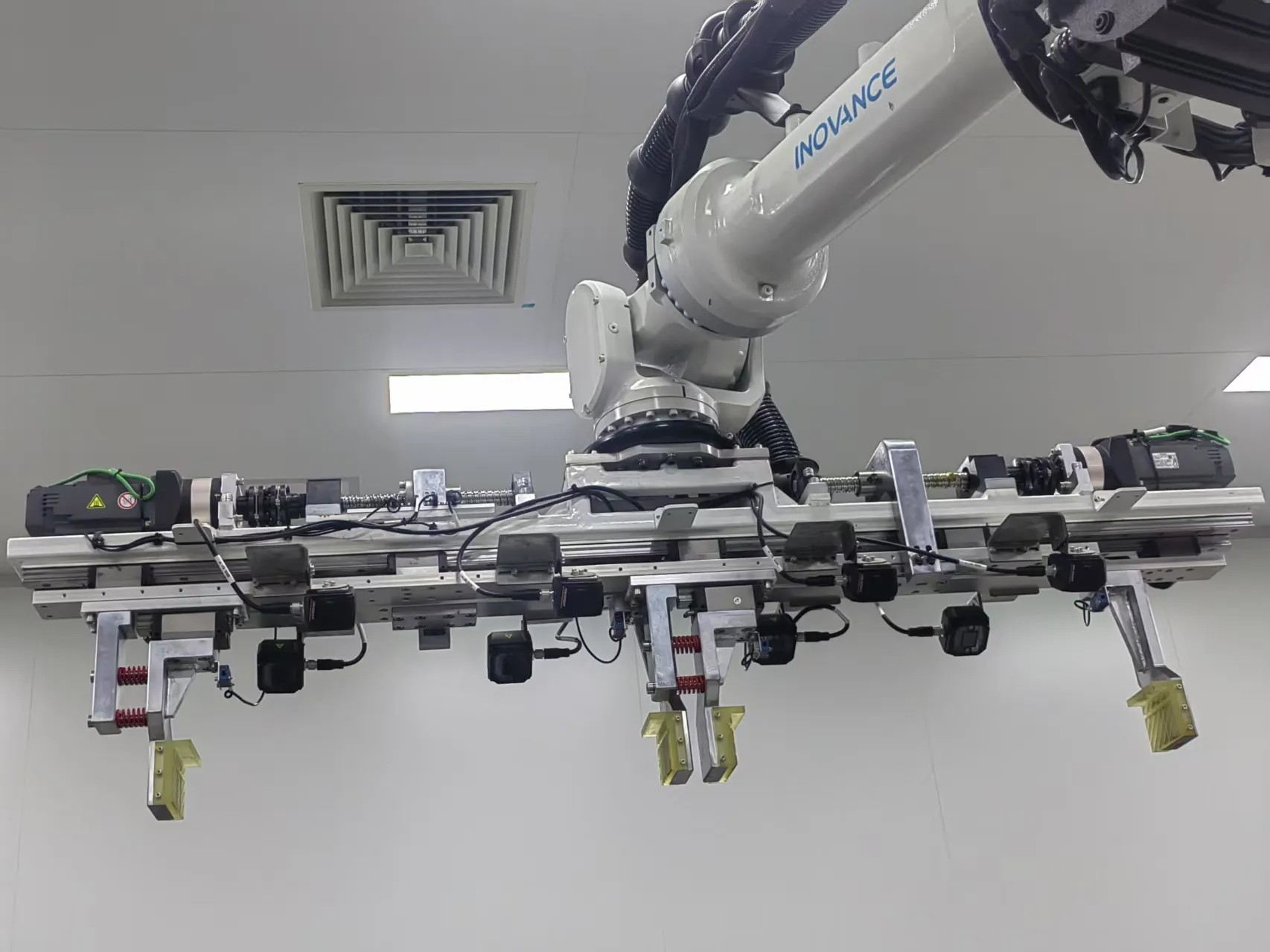

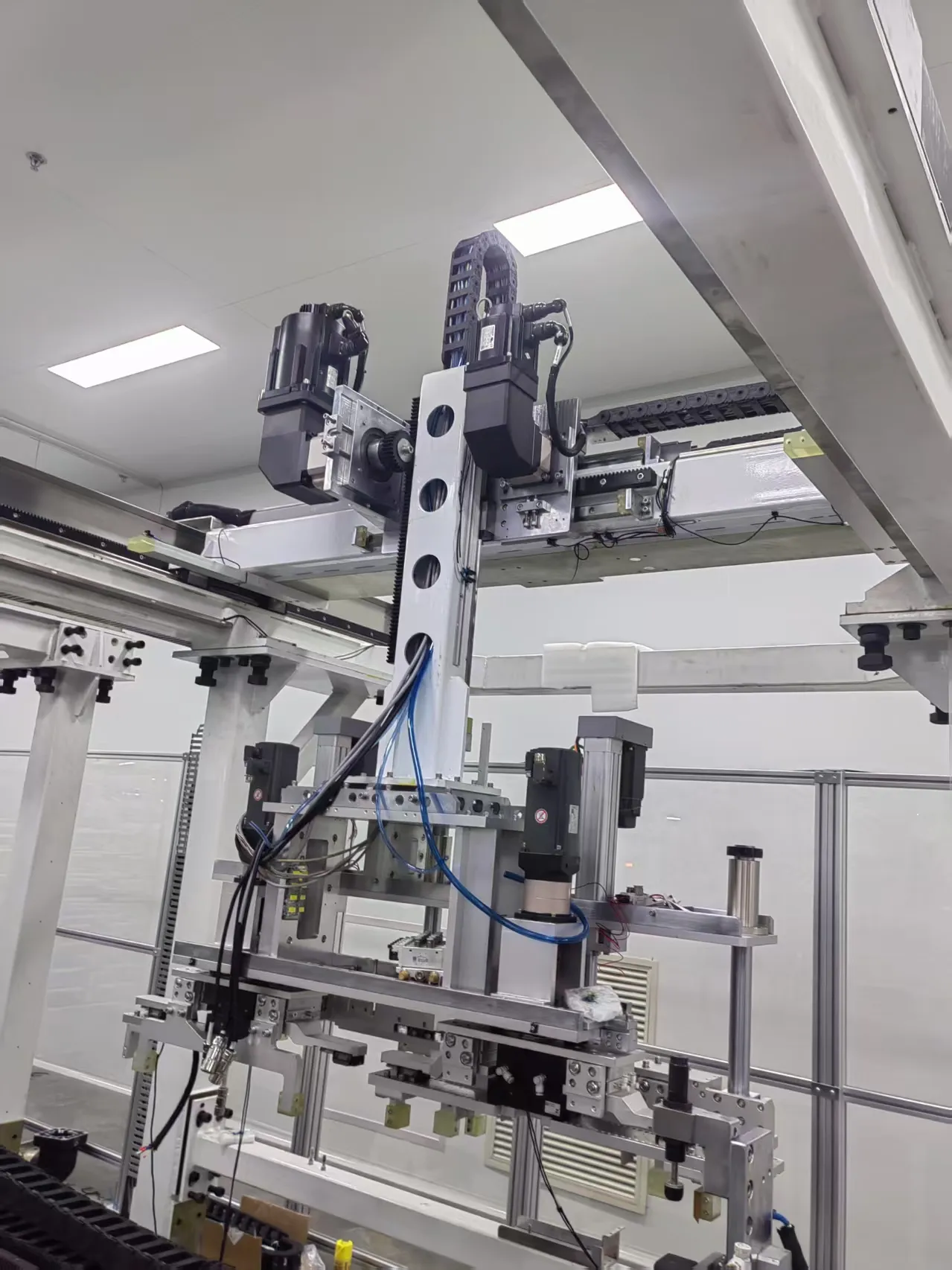

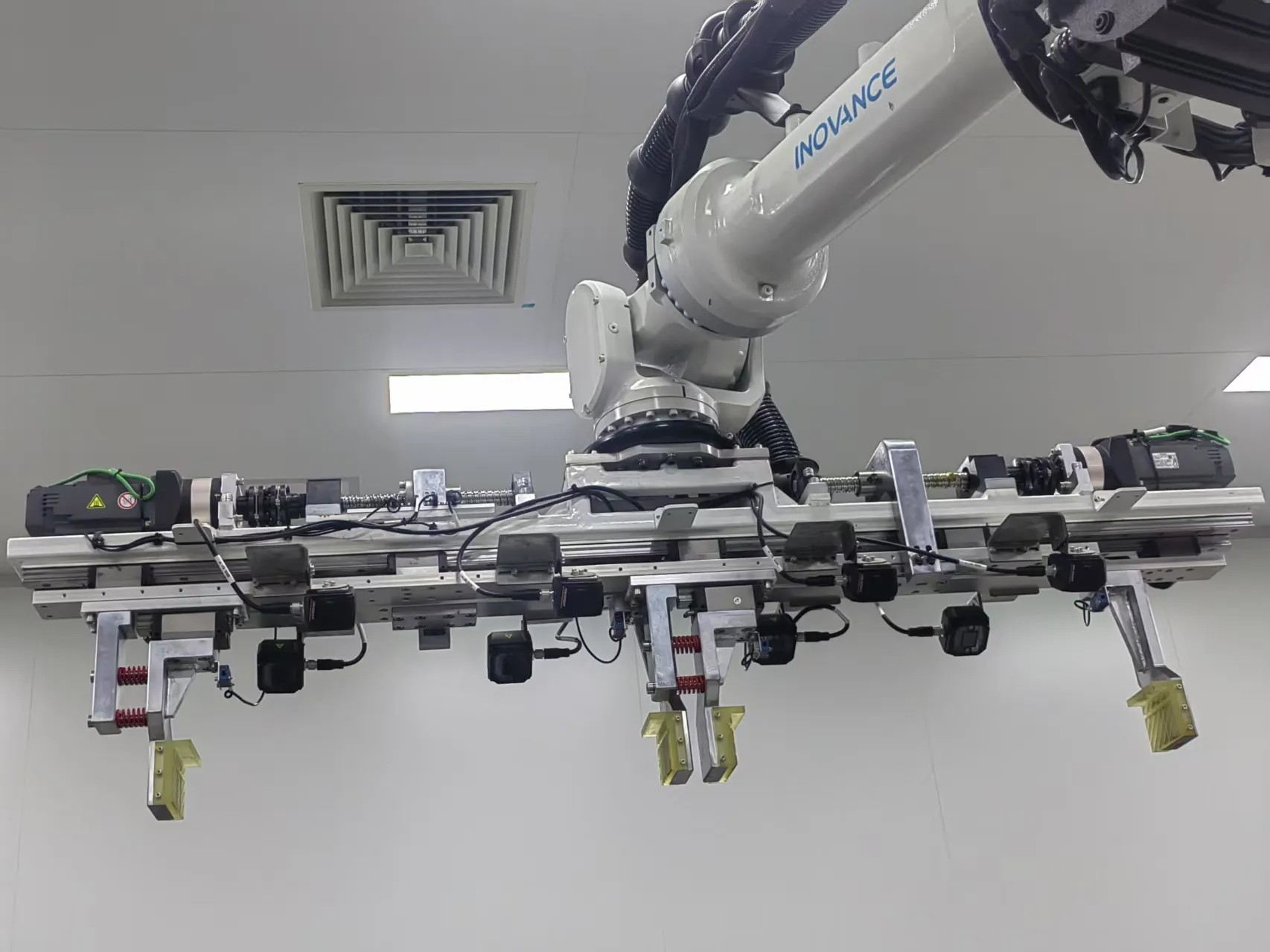

| PACK Assembly & Error-Proofing System: Utilizes INCT linear modules and servo control to achieve precise fastening and error-proof tracking. | Module Forming Servo Press: Ensures accurate deformation correction and pressure control during battery module assembly. | Battery Holding & Pressing Tray: INCT electric cylinders enable synchronized multi-point pressure holding and safety release control. | Gantry Frame & Custom Fixtures: Built on INCT linear modules for high-precision positioning and flexible movement. | Robot Custom Grippers: Tailored gripper systems integrated with robots to enhance flexibility and automation efficiency. |

|

|

|

|

|

Application Fields

• Prismatic battery module assembly lines

• Cylindrical battery PACK production lines

• Solid-state battery module assembly systems

• Energy storage battery assembly and inspection lines

Solution Advantages

✅ Complete In-house Product Range – From actuation to transmission, INCT provides a fully integrated automation solution.

✅ High Reliability – Engineered to meet the 24-hour operational demands of the new energy battery industry.

✅ Flexible and Customizable – Adaptable to different production line layouts and process requirements.

✅ Comprehensive Technical Support – INCT offers full-line selection, integration, and after-sales service assistance.

Industry Background

With the rapid growth of the new energy vehicle and energy storage industries, the manufacturing of battery modules, PACKs, and CTP systems demands ever-higher levels of precision, stability, and automation.

These production lines typically operate 24 hours a day, requiring equipment with high reliability, long service life, and flexible configuration to support diverse assembly processes.

To meet these challenges, INCT has developed a comprehensive automation solution for the new energy battery industry. The system integrates INCT’s servo presses, linear modules, ball screw & guide assemblies, gearboxes, and electric cylinders—delivering an intelligent, mechatronic platform for efficient and consistent battery assembly.

Solution Components

The solution is built upon INCT’s core products, forming a complete motion and control system:

1️⃣ INCT Servo Press

Designed for module forming and PACK press-fit processes. Offers high-precision force control and real-time pressure curve monitoring to ensure consistent quality.

2️⃣ INCT Linear Module

Rigid, high-speed linear motion platform supporting multi-axis coordination for assembly and handling stations.

3️⃣ INCT Ball Screw & Guide Assembly

Provides precise and durable linear motion, maintaining repeatability and stability under long-term operation.

4️⃣ INCT Gearbox

Delivers high torque with low backlash for efficient and smooth servo motion transmission.

5️⃣ INCT Electric Cylinder

A clean, precise, and low-maintenance alternative to pneumatic and hydraulic systems—ideal for press-fit, pushing, and holding applications.

Key Features

👉 24/7 Reliable Operation

All systems are designed with precision motion components and servo control for continuous production stability.

👉 High Accuracy and Consistency

Closed-loop control of pressure, position, and torque ensures process traceability and product uniformity.

👉 Mechatronic and Modular Design

Highly integrated components allow flexible configurations for different production layouts and cycle times.

👉 Comprehensive Product Portfolio

INCT provides a wide range of motion and automation products to support various battery structures, including prismatic, cylindrical, solid-state, and energy storage cells.

Typical Applications

| PACK Assembly & Error-Proofing System: Utilizes INCT linear modules and servo control to achieve precise fastening and error-proof tracking. |  |

| Module Forming Servo Press: Ensures accurate deformation correction and pressure control during battery module assembly. |  |

| Battery Holding & Pressing Tray: INCT electric cylinders enable synchronized multi-point pressure holding and safety release control. |  |

| Gantry Frame & Custom Fixtures: Built on INCT linear modules for high-precision positioning and flexible movement. |  |

| Robot Custom Grippers: Tailored gripper systems integrated with robots to enhance flexibility and automation efficiency. |  |

Application Fields

• Prismatic battery module assembly lines

• Cylindrical battery PACK production lines

• Solid-state battery module assembly systems

• Energy storage battery assembly and inspection lines

Solution Advantages

✅ Complete In-house Product Range – From actuation to transmission, INCT provides a fully integrated automation solution.

✅ High Reliability – Engineered to meet the 24-hour operational demands of the new energy battery industry.

✅ Flexible and Customizable – Adaptable to different production line layouts and process requirements.

✅ Comprehensive Technical Support – INCT offers full-line selection, integration, and after-sales service assistance.

Next: No Data