INCT GmbH

Blog Details

Types of Planetary Gearboxes

2025-11-21

Planetary gearboxes are valued for their high torque density, compact size, and excellent transmission efficiency. Although every planetary system includes the same fundamental elements—sun gear, planet gears, carrier, and internal ring gear—the arrangement and configuration of these components vary to meet different performance, space, and load requirements. This classification guide helps engineers identify the most suitable gearbox for industrial automation, robotics, and precision motion-control applications.

1. By Transmission Stages

1.1 Single-Stage Planetary Gearbox

A versatile and cost-efficient design featuring one set of planet gears. It provides moderate torque with a reduction ratio between 3:1 and 10:1 and maintains efficiency above 97%. Its simple structure reduces wear and minimizes backlash, making it well suited for general machinery, light-duty servo systems, and low-power motion applications.

1.2 Multi-Stage Planetary Gearbox

Developed for high-torque operation and large reduction ratios (often exceeding 100:1), this configuration stacks multiple planetary stages in series. Each additional stage increases torque output while preserving a compact form factor—an essential advantage for heavy equipment, electric vehicle drivetrains, and high-precision CNC systems. Modern multi-stage designs maintain efficiencies above 95% even with three or more stages, offering an effective balance between power density and physical size.

2. By Shaft Layout

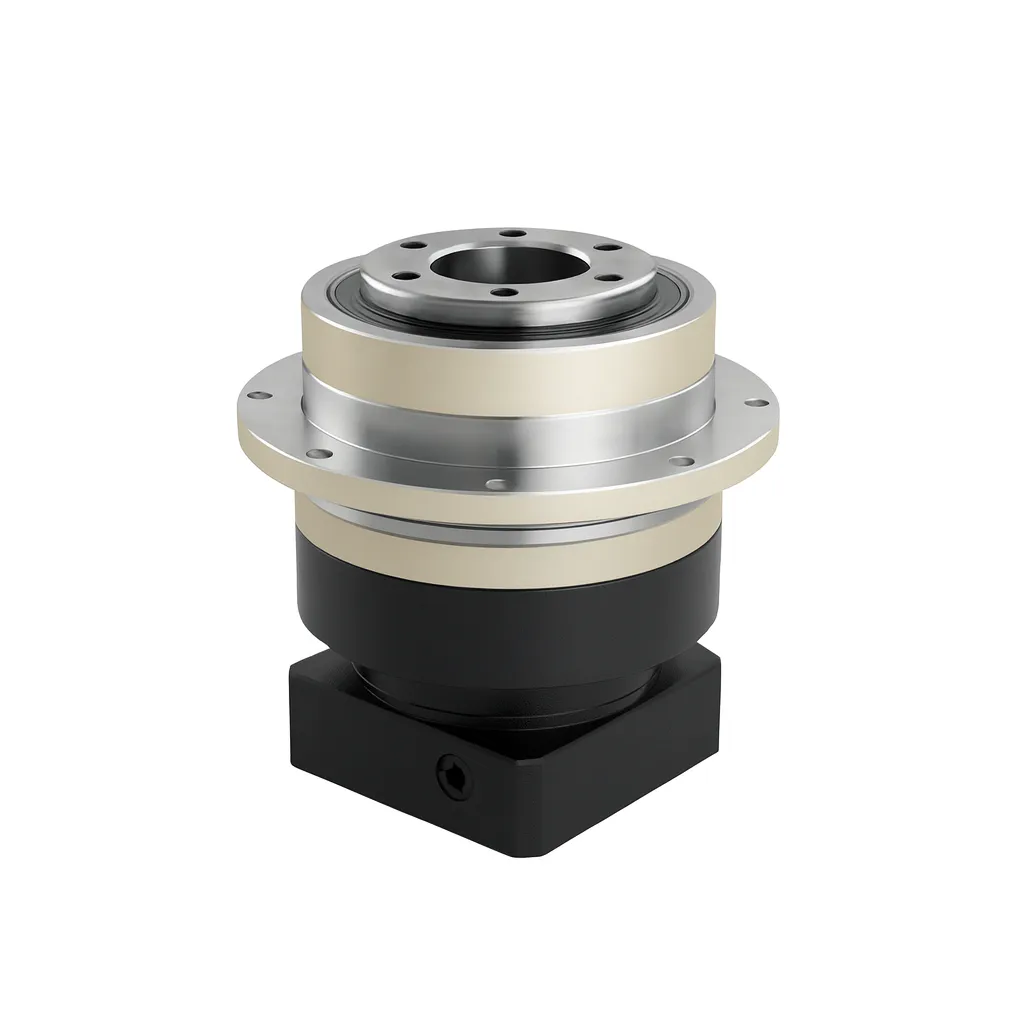

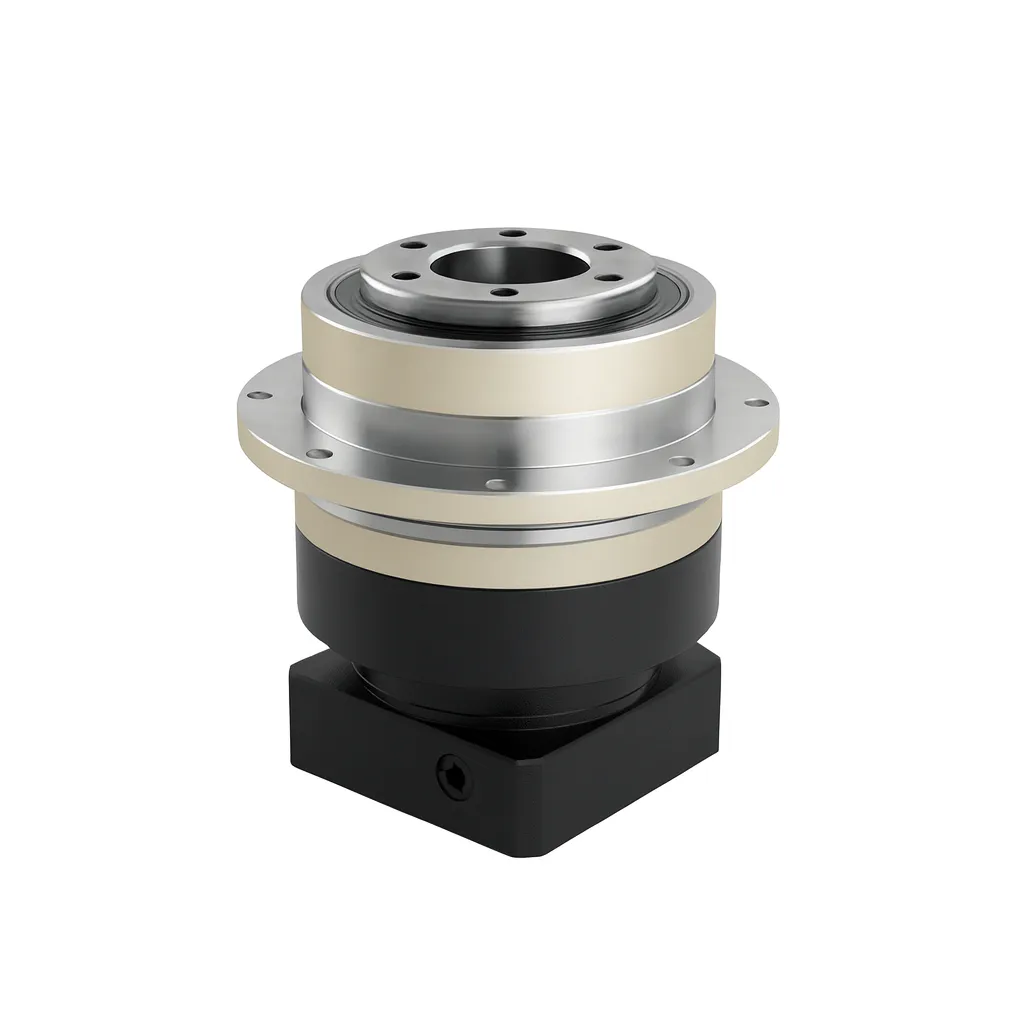

2.1 Coaxial Planetary Gearbox

With input and output shafts positioned along the same axis, this design maximizes space efficiency and distributes radial loads evenly. It eliminates alignment complications and is often used in linear actuators, compact robotic mechanisms, and automation equipment where installation space is tightly constrained.

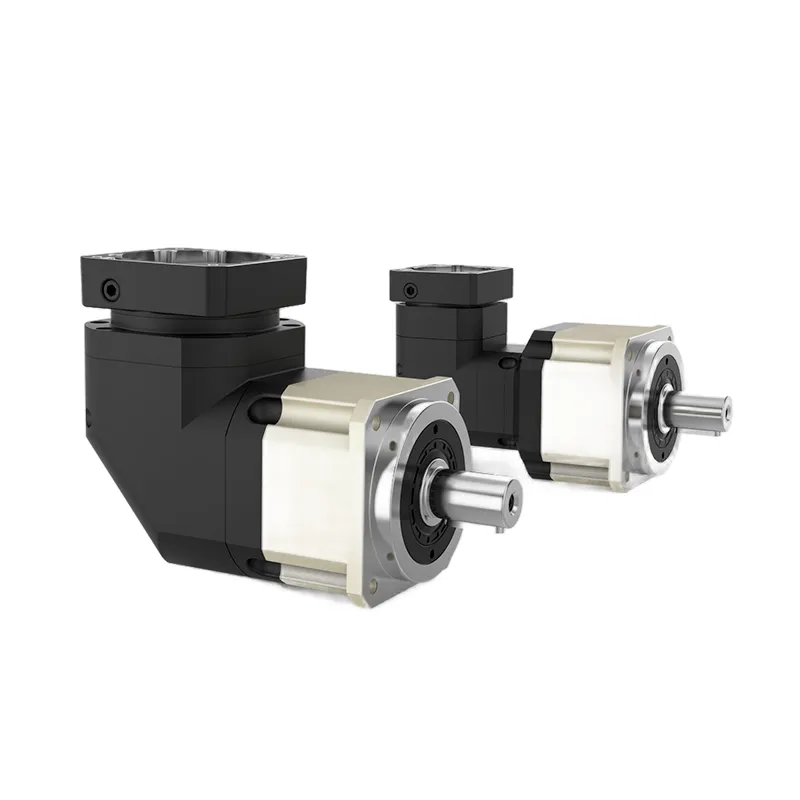

2.2 Right-Angle Planetary Gearbox

Incorporating bevel or spiral-bevel gearing, this variant redirects motion by 90 degrees without sacrificing torque capacity—industrial versions can exceed 5,000 N·m. Its flexible mounting geometry makes it an ideal solution for AGVs, conveyor systems, and machine tools that require orthogonal movement.

3. By Precision Requirement

3.1 Standard-Precision Planetary Gearbox

Featuring typical backlash levels of 3–10 arc-minutes, this category meets basic motion-control needs. Durable and cost-effective, standard-precision models are widely used in general industrial applications such as conveyors, material-handling systems, and packaging machinery where ultra-precise positioning is unnecessary.

3.2 High-Precision (Low-Backlash) Planetary Gearbox

Manufactured with tight machining tolerances, these gearboxes achieve backlash values below 1 arc-minute. They enable smooth, repeatable motion and are ideal for servo-driven robotic joints, CNC positioning systems, automated assembly lines, and other dynamic applications demanding high accuracy and responsiveness.

4. By Composite Structure

4.1 Harmonic-Planetary Hybrid Gearbox

Combining a planetary gear stage with a harmonic drive module, this hybrid achieves extremely high reduction ratios (50–500) and sub-micron positioning precision. Its low noise, compact form, and high accuracy make it suitable for aerospace actuators, surgical robots, and ultra-compact motion systems.

4.2 Cycloidal-Planetary Hybrid Gearbox

This configuration integrates planetary gears with a cycloidal mechanism, enhancing shock resistance and increasing load capacity by up to 20% compared with standard planetary models. It is commonly used in heavy-duty robots, offshore equipment, and construction machinery where high durability and impact resistance are essential.

Conclusion

Selecting the right planetary gearbox requires balancing reduction ratio (based on transmission stages), shaft layout, precision level, and overall structural complexity with application demands. Each category and subtype offers unique design strengths, enabling efficient, reliable, and high-performance motion control across a wide range of industrial environments.

Planetary gearboxes are valued for their high torque density, compact size, and excellent transmission efficiency. Although every planetary system includes the same fundamental elements—sun gear, planet gears, carrier, and internal ring gear—the arrangement and configuration of these components vary to meet different performance, space, and load requirements. This classification guide helps engineers identify the most suitable gearbox for industrial automation, robotics, and precision motion-control applications.

1. By Transmission Stages

1.1 Single-Stage Planetary Gearbox

A versatile and cost-efficient design featuring one set of planet gears. It provides moderate torque with a reduction ratio between 3:1 and 10:1 and maintains efficiency above 97%. Its simple structure reduces wear and minimizes backlash, making it well suited for general machinery, light-duty servo systems, and low-power motion applications.

1.2 Multi-Stage Planetary Gearbox

Developed for high-torque operation and large reduction ratios (often exceeding 100:1), this configuration stacks multiple planetary stages in series. Each additional stage increases torque output while preserving a compact form factor—an essential advantage for heavy equipment, electric vehicle drivetrains, and high-precision CNC systems. Modern multi-stage designs maintain efficiencies above 95% even with three or more stages, offering an effective balance between power density and physical size.

2. By Shaft Layout

2.1 Coaxial Planetary Gearbox

With input and output shafts positioned along the same axis, this design maximizes space efficiency and distributes radial loads evenly. It eliminates alignment complications and is often used in linear actuators, compact robotic mechanisms, and automation equipment where installation space is tightly constrained.

2.2 Right-Angle Planetary Gearbox

Incorporating bevel or spiral-bevel gearing, this variant redirects motion by 90 degrees without sacrificing torque capacity—industrial versions can exceed 5,000 N·m. Its flexible mounting geometry makes it an ideal solution for AGVs, conveyor systems, and machine tools that require orthogonal movement.

3. By Precision Requirement

3.1 Standard-Precision Planetary Gearbox

Featuring typical backlash levels of 3–10 arc-minutes, this category meets basic motion-control needs. Durable and cost-effective, standard-precision models are widely used in general industrial applications such as conveyors, material-handling systems, and packaging machinery where ultra-precise positioning is unnecessary.

3.2 High-Precision (Low-Backlash) Planetary Gearbox

Manufactured with tight machining tolerances, these gearboxes achieve backlash values below 1 arc-minute. They enable smooth, repeatable motion and are ideal for servo-driven robotic joints, CNC positioning systems, automated assembly lines, and other dynamic applications demanding high accuracy and responsiveness.

4. By Composite Structure

4.1 Harmonic-Planetary Hybrid Gearbox

Combining a planetary gear stage with a harmonic drive module, this hybrid achieves extremely high reduction ratios (50–500) and sub-micron positioning precision. Its low noise, compact form, and high accuracy make it suitable for aerospace actuators, surgical robots, and ultra-compact motion systems.

4.2 Cycloidal-Planetary Hybrid Gearbox

This configuration integrates planetary gears with a cycloidal mechanism, enhancing shock resistance and increasing load capacity by up to 20% compared with standard planetary models. It is commonly used in heavy-duty robots, offshore equipment, and construction machinery where high durability and impact resistance are essential.

Conclusion

Selecting the right planetary gearbox requires balancing reduction ratio (based on transmission stages), shaft layout, precision level, and overall structural complexity with application demands. Each category and subtype offers unique design strengths, enabling efficient, reliable, and high-performance motion control across a wide range of industrial environments.