INCT GmbH

Solutions Details

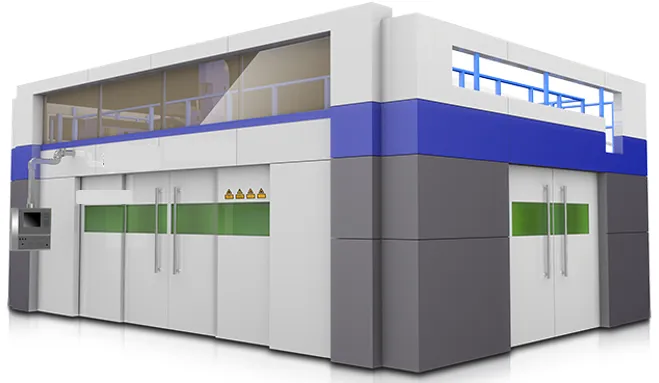

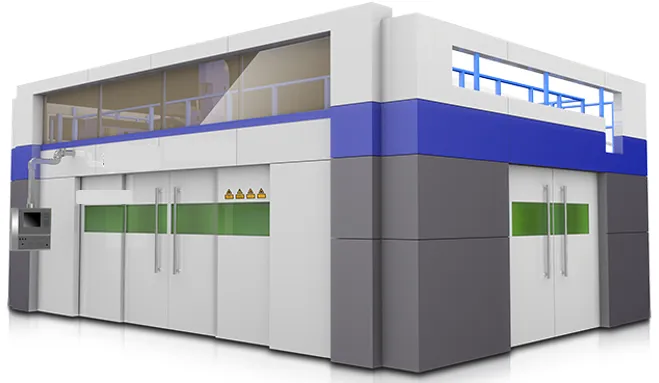

3D Five-axis Laser Cutting System Solution - Servo Motor

|

Customer Background: 1. Industry: Laser 2. Core Pain Points: Ordinary laser cutting cannot process three-dimensional workpieces

Solution: 1. Technical Highlights: Through scientific selection calculations, the efficient and fully functional system was chosen. While ensuring high-speed and high-precision requirements, drive and transmission components of appropriate specifications were selected to perfectly adapt to the system, solving 3D cutting problems and achieving optimal performance. 2. Implementation Process: Completion of system and drive/transmission scheme selection within 2 days

Core Indicators: 1. Speed: 120m/min, acceleration: 1.2g, significantly improving efficiency. 2. Positioning accuracy: ±0.05/1000mm; Repeat positioning accuracy: ±0.03mm; A/C axis positioning accuracy: ±0.015°; Repeat positioning accuracy of A/C axis: ±0.005°, which significantly improved the cutting effect. |

|

Customer Background:

1. Industry: Laser

2. Core Pain Points: Ordinary laser cutting cannot process three-dimensional workpieces

Solution:

1. Technical Highlights: Through scientific selection calculations, the efficient and fully functional system was chosen. While ensuring high-speed and high-precision requirements, drive and transmission components of appropriate specifications were selected to perfectly adapt to the system, solving 3D cutting problems and achieving optimal performance.

2. Implementation Process: Completion of system and drive/transmission scheme selection within 2 days

Core Indicators:

1. Speed: 120m/min, acceleration: 1.2g, significantly improving efficiency.

2. Positioning accuracy: ±0.05/1000mm; Repeat positioning accuracy: ±0.03mm; A/C axis positioning accuracy: ±0.015°; Repeat positioning accuracy of A/C axis: ±0.005°, which significantly improved the cutting effect.

Next: No Data