INCT GmbH

Solutions Details

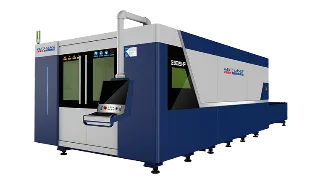

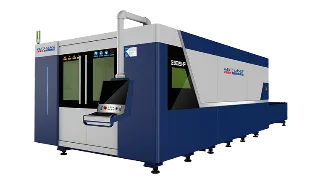

High-Speed Planar Laser Cutter Drive & Transmission Solution - Servo Motor

|

Customer Background: 1. Industry: Laser 2. Core Pain Points: The performance of high-power lasers cannot be fully utilized, with low processing efficiency and high costs. High precision and high dynamic performance are required.

Solution: 1. Product Functions: High-power laser cutting can be perfectly realized, with high processing efficiency and high precision. 2. Technical Highlights: Scientific selection ensures drive/transmission components meet high-speed and high-precision requirements, reducing costs while maximizing servo motor and transmission system performance. 3. Implementation Process: Complete the selection of drive and transmission schemes within 1 day.

Core Indicators: 1. Speed: 200m/min, acceleration: 2.8g, with greatly improved efficiency; 2. Positioning accuracy: ±0.03/1000mm, repeat positioning accuracy: ±0.02mm, so that the cutting effect is greatly improved. |

|

Customer Background:

1. Industry: Laser

2. Core Pain Points: The performance of high-power lasers cannot be fully utilized, with low processing efficiency and high costs. High precision and high dynamic performance are required.

Solution:

1. Product Functions: High-power laser cutting can be perfectly realized, with high processing efficiency and high precision.

2. Technical Highlights: Scientific selection ensures drive/transmission components meet high-speed and high-precision requirements, reducing costs while maximizing servo motor and transmission system performance.

3. Implementation Process: Complete the selection of drive and transmission schemes within 1 day.

Core Indicators:

1. Speed: 200m/min, acceleration: 2.8g, with greatly improved efficiency;

2. Positioning accuracy: ±0.03/1000mm, repeat positioning accuracy: ±0.02mm, so that the cutting effect is greatly improved.