INCT GmbH

Blog Details

Planetary Gear Series — Chapter 3

2025-12-24

How to Select a Planetary Gearbox (Selection Guide)

This is Chapter 3 of our Planetary Gear Series. Building upon the fundamentals and mechanics covered in Chapters 1 and 2, we now delve into the core of practical engineering.

In this chapter, we move from theory to application and focus on a critical engineering task: selecting the correct planetary gearbox for real-world use. Improper gearbox selection can lead to premature failure, poor performance, excessive noise, or unnecessary cost.

This guide will help you make informed, engineering-driven decisions.

In this chapter, you will learn:

1. How to calculate the required output torque

2. How to select the correct reduction ratio

3. Axial and radial load considerations

4. Mounting type and motor interface selection

5. Common gearbox selection mistakes to avoid

Step 1: Calculate Required Torque

The first and most critical step is determining the required output torque of the gearbox.

Formula: Required Torque = Load × Arm Length × Safety Factor

Where:

⚙️ Load is the applied force or mass

⚙️ Arm Length is the effective lever arm

⚙️ Safety Factor accounts for shock loads, acceleration, and uncertainty

This is closely related to the real‑world operating constraints discussed in Chapter 5: Operating Within Real‑World Constraints.

Typical Safety Factors:

Light load: 1.5 – 2.0

Medium load: 2.0 – 2.5

Heavy load / shock load: 2.5 – 3.5

Selecting an insufficient safety factor is one of the most common causes of gearbox overload and failure.

Step 2: Choose the Reduction Ratio

The reduction ratio directly affects output torque, speed, positioning accuracy, and system inertia.

Ratio selection should be based on application requirements, not arbitrary preference.

|

Application |

Recommended Reduction Ratio |

|

Robotics |

5:1 / 7:1 / 10:1 |

|

Conveyor systems |

15:1 – 30:1 |

|

Heavy machinery |

50:1 – 100:1 |

|

Precision positioning |

Small ratio with low backlash |

Higher ratios provide higher torque but reduce output speed and dynamic responsiveness.

For precision motion systems, low backlash is often more important than high ratio.

Step 3: Axial and Radial Load Considerations

Planetary gearboxes are designed primarily for torque transmission, but axial and radial loads must never be ignored.

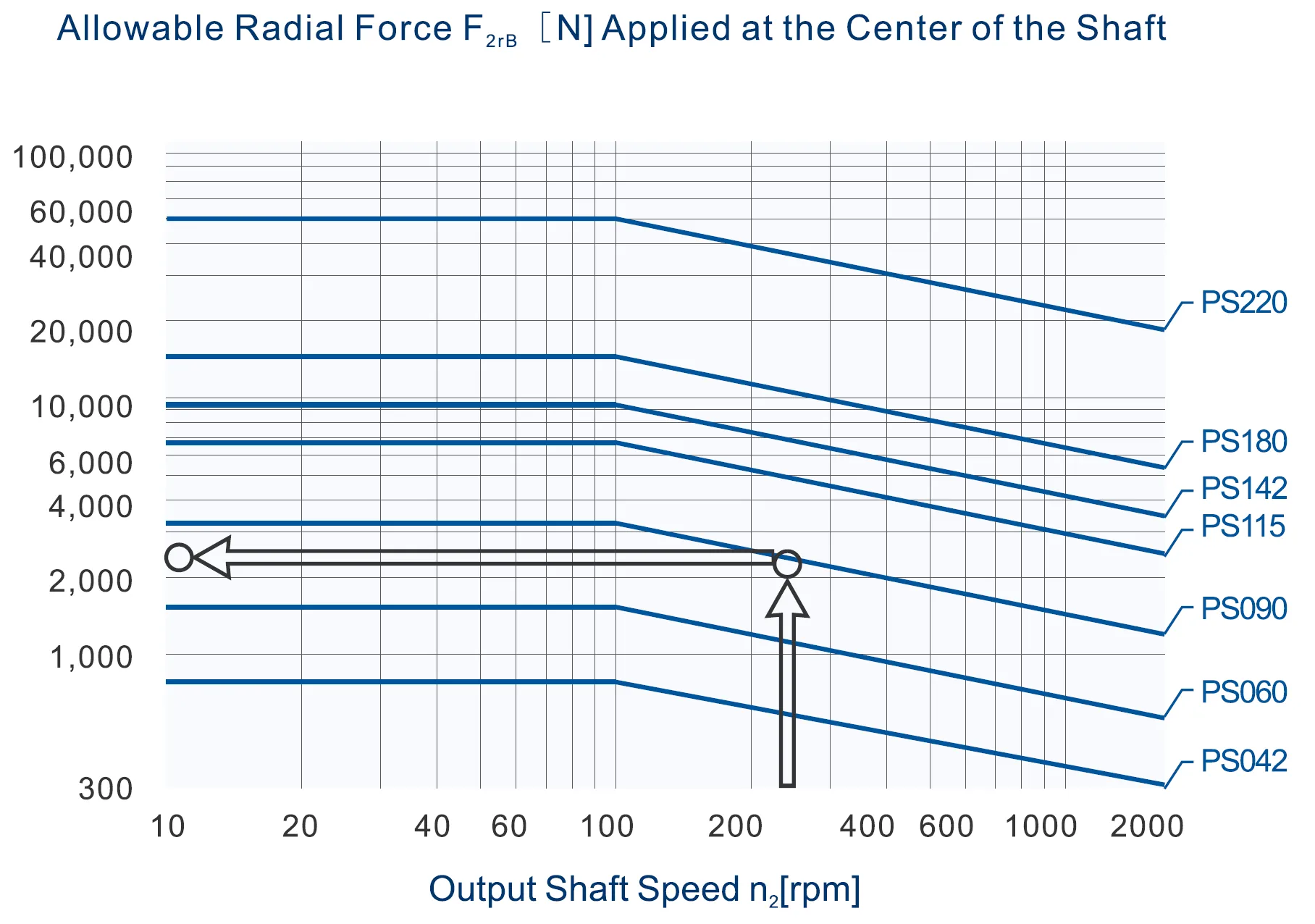

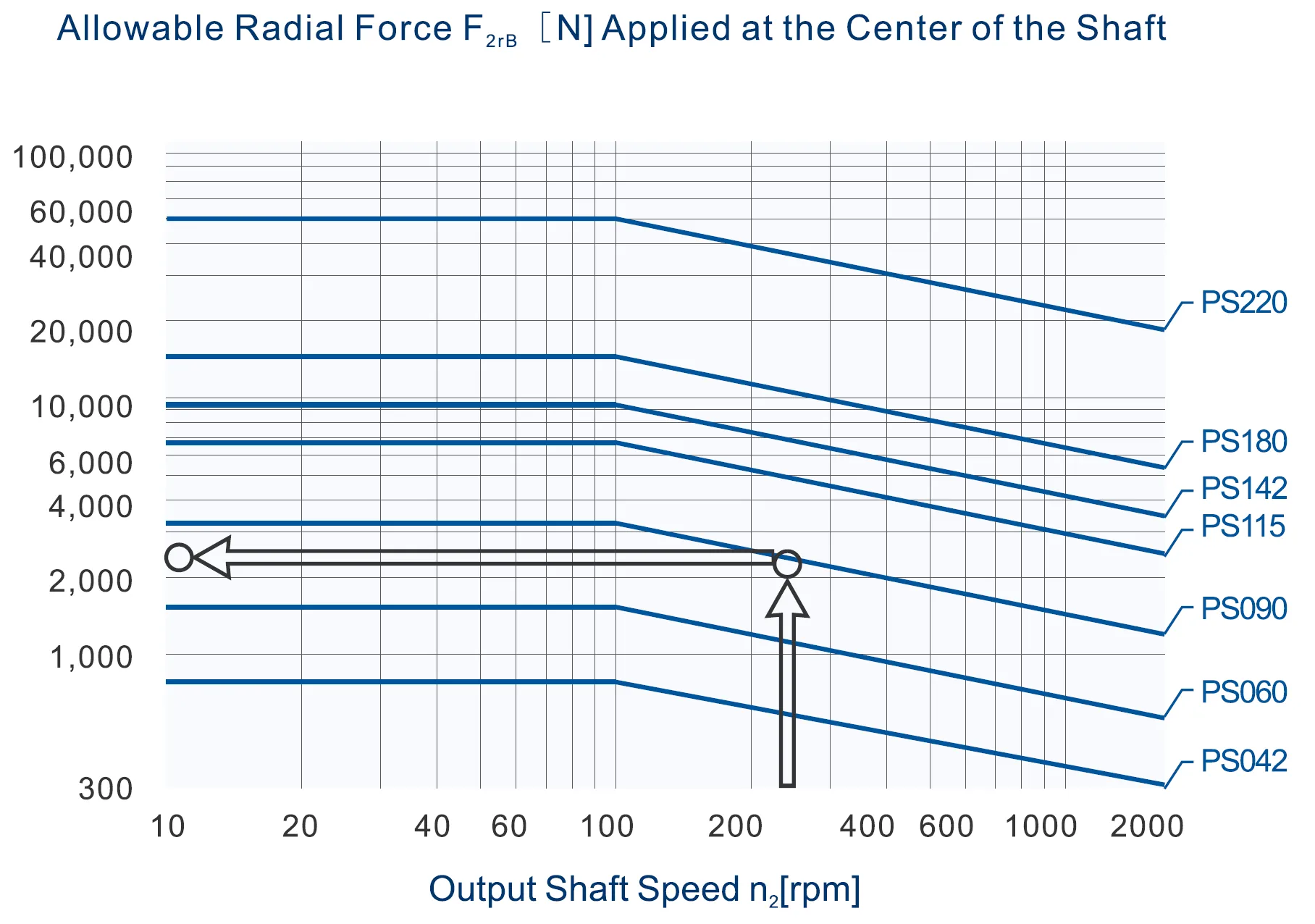

Always refer to the manufacturer's allowable axial and radial load charts. As shown below is the allowable radial force curve for the INCT PS series gearbox.

Exceeding these limits may result in:

👉 Bearing damage

👉 Reduced service life

👉 Degraded positioning accuracy

If your application involves significant external loads, consider:

👉 Reinforced bearings

👉 External support bearings

👉 Flange-mounted output designs

Step 4: Mounting Type & Motor Interface

(These integration considerations are part of the broader system‑level thinking discussed in Chapter 5)

Mechanical compatibility is essential for reliable installation and long-term operation.

Key factors to verify:

✅ Inline or right-angle configuration

✅ Shaft output or flange output

✅ Motor shaft diameter

✅ Bolt circle and pilot diameter

Always ensure the gearbox is fully compatible with the selected motor standard (servo or stepper) to avoid misalignment and vibration issues.

Common Planetary Gearbox Selection Mistakes

Avoid the following frequent errors:

❌ Ignoring load and torque calculation

❌ Selecting based on price alone

❌ Overlooking backlash and noise requirements

❌ Failing to review service life and duty cycle curves

A properly selected gearbox improves system efficiency, reliability, and total cost of ownership.

How to Select a Planetary Gearbox (Selection Guide)

This is Chapter 3 of our Planetary Gear Series. Building upon the fundamentals and mechanics covered in Chapters 1 and 2, we now delve into the core of practical engineering.

In this chapter, we move from theory to application and focus on a critical engineering task: selecting the correct planetary gearbox for real-world use. Improper gearbox selection can lead to premature failure, poor performance, excessive noise, or unnecessary cost.

This guide will help you make informed, engineering-driven decisions.

In this chapter, you will learn:

1. How to calculate the required output torque

2. How to select the correct reduction ratio

3. Axial and radial load considerations

4. Mounting type and motor interface selection

5. Common gearbox selection mistakes to avoid

Step 1: Calculate Required Torque

The first and most critical step is determining the required output torque of the gearbox.

Formula: Required Torque = Load × Arm Length × Safety Factor

Where:

⚙️ Load is the applied force or mass

⚙️ Arm Length is the effective lever arm

⚙️ Safety Factor accounts for shock loads, acceleration, and uncertainty

This is closely related to the real‑world operating constraints discussed in Chapter 5: Operating Within Real‑World Constraints.

Typical Safety Factors:

Light load: 1.5 – 2.0

Medium load: 2.0 – 2.5

Heavy load / shock load: 2.5 – 3.5

Selecting an insufficient safety factor is one of the most common causes of gearbox overload and failure.

Step 2: Choose the Reduction Ratio

The reduction ratio directly affects output torque, speed, positioning accuracy, and system inertia.

Ratio selection should be based on application requirements, not arbitrary preference.

|

Application |

Recommended Reduction Ratio |

|

Robotics |

5:1 / 7:1 / 10:1 |

|

Conveyor systems |

15:1 – 30:1 |

|

Heavy machinery |

50:1 – 100:1 |

|

Precision positioning |

Small ratio with low backlash |

Higher ratios provide higher torque but reduce output speed and dynamic responsiveness.

For precision motion systems, low backlash is often more important than high ratio.

Step 3: Axial and Radial Load Considerations

Planetary gearboxes are designed primarily for torque transmission, but axial and radial loads must never be ignored.

Always refer to the manufacturer's allowable axial and radial load charts. As shown below is the allowable radial force curve for the INCT PS series gearbox.

Exceeding these limits may result in:

👉 Bearing damage

👉 Reduced service life

👉 Degraded positioning accuracy

If your application involves significant external loads, consider:

👉 Reinforced bearings

👉 External support bearings

👉 Flange-mounted output designs

Step 4: Mounting Type & Motor Interface

(These integration considerations are part of the broader system‑level thinking discussed in Chapter 5)

Mechanical compatibility is essential for reliable installation and long-term operation.

Key factors to verify:

✅ Inline or right-angle configuration

✅ Shaft output or flange output

✅ Motor shaft diameter

✅ Bolt circle and pilot diameter

Always ensure the gearbox is fully compatible with the selected motor standard (servo or stepper) to avoid misalignment and vibration issues.

Common Planetary Gearbox Selection Mistakes

Avoid the following frequent errors:

❌ Ignoring load and torque calculation

❌ Selecting based on price alone

❌ Overlooking backlash and noise requirements

❌ Failing to review service life and duty cycle curves

A properly selected gearbox improves system efficiency, reliability, and total cost of ownership.